HUNTINGTON BEACH, Calif., July 1, 2025 – From the Cleveland 588 Tour Action to the ground-breaking RTX ZipCore, Cleveland Golf Wedges have long been iconic keystones of golf history, present, and future. Naturally, for the next chapter of our Wedge leadership and innovation, we set out to raise the bar yet again. With a back-to-basics approach exploring all-new materials, fundamentally transforming how we design and manufacture our flagship products, we’ve improved Cleveland Golf Wedges in every way possible and pushed the industry into an exciting new era of short game performance.

Several years ago, unbeknownst to the industry at large, Cleveland Golf research teams embarked on a material science exploration to discover a new metal alloy for future Cleveland Golf Wedges. It quickly became clear, however, that if a material existed on Earth which could improve Wedge performance in every measurable way, we would have adopted it long ago. That left us with the singular option to make our own. Led by our in-house Ph.D. metallurgist, our engineers worked hand-in-hand with manufacturing partners and their cutting-edge foundry techniques to create a brand-new metal, entirely optimized for golf club performance. After countless iterations and exhaustive testing, we’d done it. We’d crafted an entirely new alloy, exclusive to Cleveland Golf, and we called it Z-Alloy.

BENEFITS OF Z-ALLOY

A brand-new, proprietary material, Z-Alloy improves upon 8620 steel—the most common Wedge material—in four key areas:

FEEL

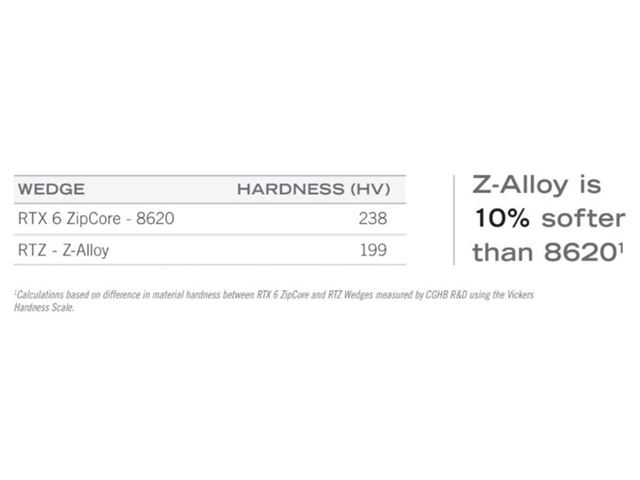

While feel is difficult to quantify, experts consider material hardness a good barometer for how firm or soft a Wedge will feel at impact. Using the Vickers scale of material hardness measurement, Z-Alloy is 10% softer than 86201. It also has roughly half as much variability in its hardness since its final properties are controlled by a tempering temperature instead of a cooling rate. This results in a more consistent internal structure.

DENSITY

Z-Alloy was engineered for consistent casting with few flaws and imperfections, similarly to 8620. But its significantly lower density makes it far superior, giving our R&D Team never-before-seen levels of flexibility. It grants more freedom to optimize CG placement and MOI, producing exciting performance improvements without undesirable shaping or aesthetics in the final product.

Switching to Z-Alloy gave RTZ designers ~6 grams of discretionary mass for CG repositioning. This is invaluable as our designers can add material to the muscle, flange, or elsewhere to relocate those grams and position the CG exactly where it benefits performance. Which is precisely how we’ve improved launch and spin profiles for every individual loft in the RTZ lineup.

BENDABILITY/MATERIAL HARDNESS

When we launch a new Wedge, one of the first questions fitters ask is: “Can we bend it?” With that in mind, we worked hard to ensure RTZ Wedges offer as much or more bendability than previous generations. Plus, while Z-Alloy still meets all stringent durability requirements, its softer makeup means it’s easier for fitters to bend with precision. Similarly, Z-Alloy was made to be just as grindable as our previous generation Wedges, satisfying the demand for grind customization by advanced golfers.

DURABILITY

While Z-Alloy is softer than the traditional 8620, it sacrifices zero durability compared to our past Wedges. Z-Alloy is higher in chromium and carbon as compared to 8620. These elements positively influence the material’s wear resistance in normal golf conditions. For the golfer, that translates to better groove durability and more consistent performance over the lifetime of the Wedge. Further, Z-Alloy doesn’t rust, vastly improving groove durability for our raw Tour Rack finish.

RUST IS A BUST?

Rust erodes groove geometry. Rust is bad for long-term performance. And rust has a negative impact on our spin enhancing groove technologies like UltiZip and HydraZip. This may seem to contradict what you have heard about rust, but it’s true: rust does not help spin performance.

While most Wedges are plated in nickel and chrome, specifically meant to keep the head and grooves from developing a rusty appearance, raw—or “unplated” Wedges—are sought after by tour professionals. This is because pros often opt to adjust the grinds of their Wedges to dial-in preferred performance, which is best done with a raw Wedge. Additionally, raw Wedges cut down on glare, another important consideration for pro players.

But until Z-Alloy, all raw Wedges inevitably rusted. That’s led to a near mythic narrative amongst amateur players who believe that tour pros choose raw Wedges because rust on a Wedge face “bites” into golf balls at impact, leading to more backspin and stopping power.

Here’s what that story gets wrong: the vast majority of Tour players never let the faces of their Wedges rust. They use and replace their Wedges far too often, as they know a face of fresh grooves is more potent than a worn one. Conversations with our own tour staff confirmed this: the impact area on nearly every tour player’s Wedge is raw but not rusted.

Ultimately, the fact is: every time rust flakes off a Wedge face, its carefully designed, milled, and inspected grooves go out of spec, its lasered roughness pattern is eroded, and its fine-tuned hydrophobic face blast is tarnished. We put monumental effort into the design and precise tolerances of our grooves and surface treatments. We want the maximum benefits of those technologies to serve our players as long as possible.

But you don’t just take our word for it. The data below proves it.

RAW PERFORMANCE: METHODOLOGY AND RESULTS

To test our belief in the benefits of rust-free Wedges, R&D pitted raw Z-Alloy Wedges against raw 8620 Wedges in a series of spin performance tests. We began with three, raw, unused 8620 Wedges (which were rusted in a controlled way) and three, raw, unused Z-Alloy wedges. Then we had an elite third-party player hit 80 bunker shots with all six wedges to simulate wear from dozens of rounds of golf2.

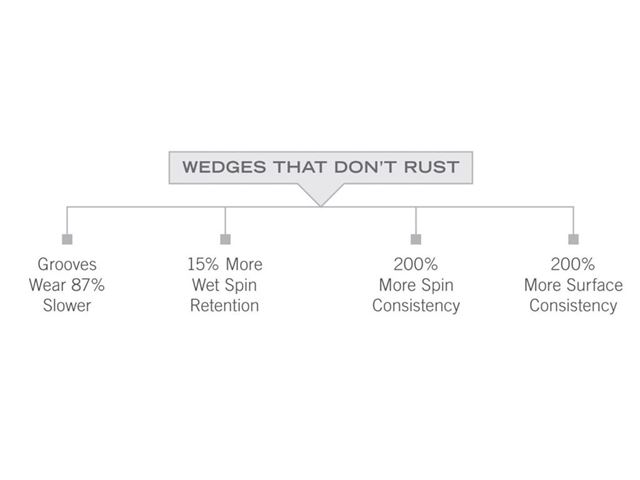

We then brought those worn Wedges into the lab, loaded each into our swing robot, and evaluated their spin performance. After extensive testing, we found that rusted grooves wore 87% faster, on average3. And, the rusted Wedge saw a 15% reduction in wet spin retention compared to our non-rusting RTZ Wedge with Z-Alloy4.

Rust on wedges cause grooves to wear 87% faster, on average.

2Wear for each club was done by a third-party elite player (plus handicap) hitting 80 bunker shots (corresponding to 80 rounds of wear based on Arccos data). Wet spin retention determined by the relative difference in wet spin across RTX 6 ZipCore and RTZ Wedges worn, and robot tested under the same conditions.

3Groove area was measured before and after wear, then overlaid using the USGA GrooveScan system (The same method the USGA uses to test for groove conformance). At least 9 grooves were measured at 5 separate locations (6mm heelside, 3mm heelside, center, 3mm toeside, and 6mm toeside) for a total of 90 overall groove measurements per club. The area difference was then averaged across all overlays to determine the absolute wear. Average wear of RTX 6 ZipCore Wedges divided by average wear of RTZ Wedges equals 187%.

4Company claims based on robot testing with ForesightTM GC QuadTM of raw RTX 6 ZipCore rusted worn vs raw RTZ worn 58-degree Wedges. Test conditions were with a wet ball, 5mm below center contact, a robot swing speed of 76mph, and 20 shots per Wedge across 3 Wedges. Trademarks are the property of respective owners.

Our extensive testing helped us observe one final insight: Wedges rust inconsistently. Rust patterns on club faces are not homogeneous even when rusted in the same environments. And the rust pattern on a Wedge face will differ from rusted Wedge to rusted Wedge. Our R&D team tested this by measuring the difference in spin between new, non-rusted RTX 6 ZipCore Wedges, and new rusted RTX 6 ZipCore Wedges. We found that non-rusted raw Wedges have significantly better overall spin5 consistency and surface6 consistency by a measure of 200%.

5Company claims based on robot testing with ForesightTM GC QuadTM of new RTX 6 ZipCore raw rusted Wedges vs new RTX 6 ZipCore raw Wedges. Test conditions were with a wet ball, wet paper, and dry ball at center contact, a robot swing speed of 76mph, and 120 shots per Wedge (40 per condition) across 3 58-degree Wedges (6 Total: 3 new and 3 new+rusted). Overall spin consistency determined by the average standard deviation across three Wedges robot tested under the same conditions above.

6200% Number Measured as difference between new raw RTX 6 ZipCore and new + rusted raw RTX 6 ZipCore. Surface consistency determined by taking the standard deviation of roughness and metrology metrics (Ra, Rz, and YRDq). Average of 3 Wedges with 5 roughness line scans per Wedge (center, and 3mm on both the heel and toe side) in both new and new + rusted states using RTX 6 ZipCore raw Wedges.

RUST CONCLUSIONS AND FINAL THOUGHTS

This data and more led us to the ultimate consensus that rust-free Z-Alloy was the best direction for RTZ and the future of Cleveland Golf. Its material properties improve on 8620 in nearly every way, adding tangible benefits that directly impact on-course play.

Our raw Tour Rack Wedges made with Z-Alloy maintain many of the benefits of traditional raw 8620 Wedges, while also being rust proof in normal golf conditions. This means:

- Raw Z-Alloy Wedges are glare resistant at address

- The grooves on raw Z-Alloy Wedges wear 87% slower compared to raw, rusted, 8620 Wedges, which unlocks maximum groove technology benefits for longer

- Raw RTZ Z-Alloy Wedges retain 15% more wet spin compared to raw, rusted 8620 RTX 6 ZipCore Wedges

- Your non-rusted, raw, Tour Rack Wedges have significantly better overall spin and surface consistency by a measure of 200% compared to a new, rusted, raw 8620 Wedge

Z-Alloy is a unique technology that will help to deliver real, measurable on-course performance improvements. We are excited for golfers to try the RTZ Wedges and experience the difference Z-Alloy can make for themselves.